Newburyport, MA 01950

Call 978.499.8950

Fax: 978.499.8967

Email Us

About Us

Hard Chrome

Electropolish

Contact Us

50 Parker Street, Unit #5

Newburyport, MA 01950

Call 978.499.8950

Fax: 978.499.8967

Email Us

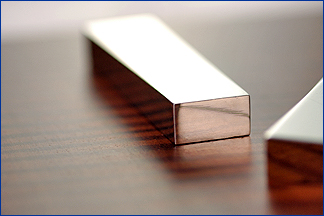

Electropolish

Why Electropolish?

Conventional mechanical finishing systems tend to smear, bend, stress and even fracture the crystalline metal surface to achieve smoothness or luster. Electropolish offers the advantages of removing metal from the surface producing a unidirectional pattern that is both stress and occlusion free, microscopically smooth, and often highly reflective. Additionally, improved corrosion resistance and passivity are achieved on many ferrous and non ferrous alloys. The process micro and macro polishes the metal part. Micro-polishing accounts for the brightness and macro-polishing accounts for the smoothness of the part.

Conventional mechanical finishing systems tend to smear, bend, stress and even fracture the crystalline metal surface to achieve smoothness or luster. Electropolish offers the advantages of removing metal from the surface producing a unidirectional pattern that is both stress and occlusion free, microscopically smooth, and often highly reflective. Additionally, improved corrosion resistance and passivity are achieved on many ferrous and non ferrous alloys. The process micro and macro polishes the metal part. Micro-polishing accounts for the brightness and macro-polishing accounts for the smoothness of the part.Deburring is accomplished quickly because of the higher current density on the burr, and because oxygen shields the valleys, enabling the constant exposure of the tip of the burr.

Because the part is bathed in oxygen, there is no hydrogen embrittlement to the part. In fact, Electropolishing is like a stress-relieve anneal. It will actually remove hydrogen from the surface.

Another benefit is that bacteria cannot successfully multiply on a surface devoid of hydrogen. This makes Electropolishing ideal for medical, pharmaceutical, semiconductor, and food-processing equipment and parts. The combination of no directional lines due to mechanical finishing, plus a surface relatively devoid of hydrogen, results in a hygienically clean surface where no bacteria or dirt can multiply or accumulate.

What is Electropolish?

The Electropolish process smoothens, polishes, deburrs, and cleans steel, stainless steel, copper alloys, and aluminum alloys in an electrolytic bath. The process selectively removes high points on metal surfaces, giving the surface a high luster.

The Electropolish process smoothens, polishes, deburrs, and cleans steel, stainless steel, copper alloys, and aluminum alloys in an electrolytic bath. The process selectively removes high points on metal surfaces, giving the surface a high luster.The metal part is immersed in the Electropolish solution and subjected to direct current (DC). The metal part is made anodic (+) and a metal cathode (-) is used. The direct current the flows from the anode, which becomes polarized, allowing metal ions to diffuse through the film to the cathode, removing metal at a controlled rate. The amount of metal removed depends on the specific bath, temperature, current density, and the particular alloy being electropolished.

What are the Benefits of Electropolish?

|

|

Massachusetts (MA) Website Design Development